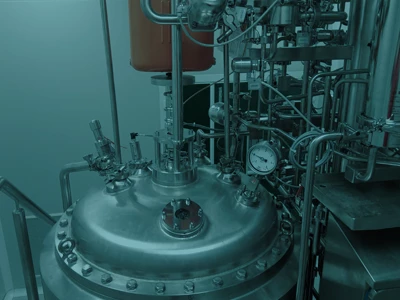

Bioreactors and fermenters

Technology that boosts your production

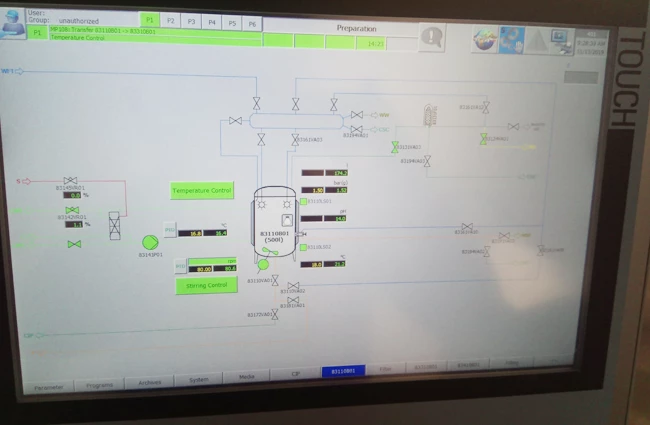

Absolute control over every parameter

Temperature, pH, dissolved oxygen and agitation adjusted for optimum conditions for each crop.

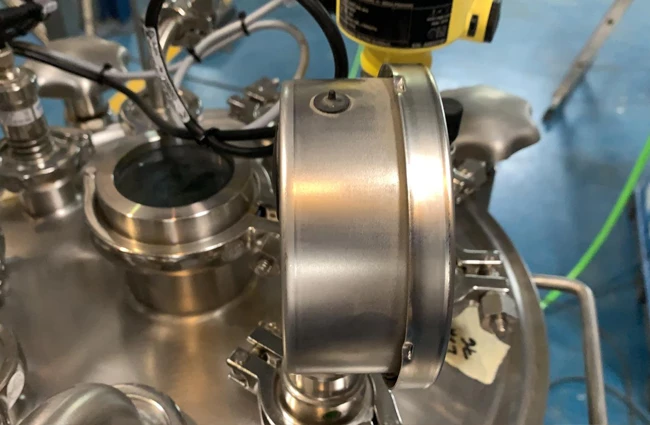

Automated cleaning

CIP/SIP compliant design eliminates risk and ensures purity in every batch.

Guaranteed scalability

From research to GMP production, with volumes adapted to the needs of each stage.

User Friendly interface

User-friendly HMI with PLC and SCADA minimises human error and ensures full traceability.

Biopharmaceutical production is error-free. Our bioreactors and fermenters are designed to ensure consistent results, safe processes and the scalability your plant needs to grow without compromising quality and sustainability.

Equipment that adapts to your needs

Every challenge is a brake on progress. That’s why we design teams that not only solve problems, but anticipate needs.

Worried about inconsistent results?

Our bioreactors and fermenters offer total control over critical parameters such as temperature, pH and dissolved oxygen. The result: consistent processes and quality-assured products in every batch.

Does your scalability stop in the lab?

With adaptable equipment and customised solutions, we are aligned with our mission to provide innovative technology that optimises production processes in the biopharmaceutical and biotechnology industry.

Feel like you’re wasting time and resources?

Our technology optimises every stage of the process, minimising downtime and maximising operational efficiency so nothing goes to waste.

Are regulations keeping you up at night?

We design equipment that complies with the most stringent regulations, such as GMP and FDA, simplifying audits and ensuring compliance at every step.

Bioreactors and Fermenters

Technology that boosts your production

Advanced technology and ease of use

Complex and unwieldy equipment is not an option. We know you need tools that work with you. That’s why at Pharmabios we create bioreactors and fermenters that combine advanced technology with ease of use:

Simple operation

Each device is designed to integrate seamlessly into your daily processes, eliminating unnecessary learning curves.

Intelligent automation

We minimise human error with systems that ensure absolute precision and control.

Technical support that backs you up:

When a challenge arises, you need fast and effective solutions.

Who do we design our equipment for?

Biopharmaceuticals

needing reproducible processes and reliable results in each batch.

Research laboratories

With an absolute focus on precision and control of each parameter.

Industrial production plants

Demanding flexible, GMP-compliant equipment, ready to grow with the market.

Whatever your goal, our bioreactors and fermenters are designed to make every process run smoothly and efficiently.

Because we understand that your production success starts with custom-designed tools.

Reproducible results

Uniformity and quality guaranteed in each batch, no exceptions.

Absolute adaptability

Full customisation, from volume to control parameters.

Carefree compliance

Equipment designed to effortlessly audit and exceed any regulation.

Improved operational efficiency

Cost reduction through compact design and optimisation of resources.

If quality is your priority, we are here to help you achieve it.

Pharmabios Bioreactors and Fermenters

Our bioreactors and fermenters are specifically designed for the pharmaceutical and biotech industry.

Why Pharmabios

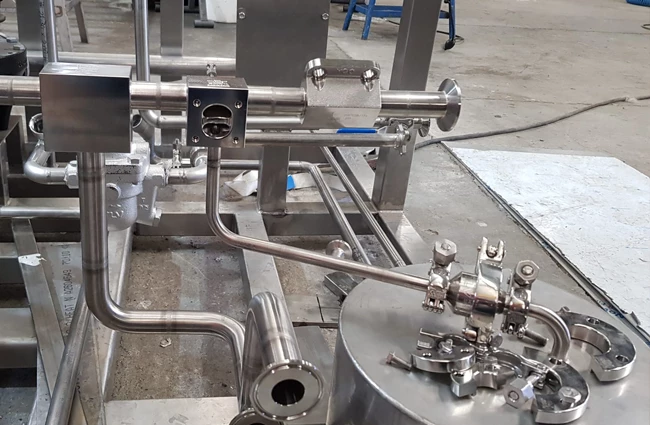

Optimised design for excellence

Ultra-polished surfaces (roughness Ra < 0.5 µm) and minimal dead zones (L < 3D) ensure the elimination of cross-contamination risks. EPDM diaphragm valves and precise configurations maximise cleanliness and safety.

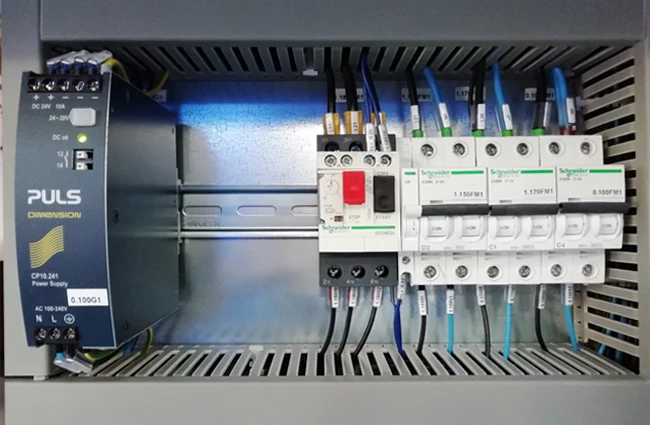

Automation designed to keep you in control

With Siemens SCADA and PLC systems, you have full access to every parameter in real time, reducing the possibility of errors and maximising operational efficiency.

Meets the most stringent regulations

Designed to comply with GMP and other international regulations, our equipment doesn’t just meet standards, it exceeds them, guaranteeing audits without surprises.

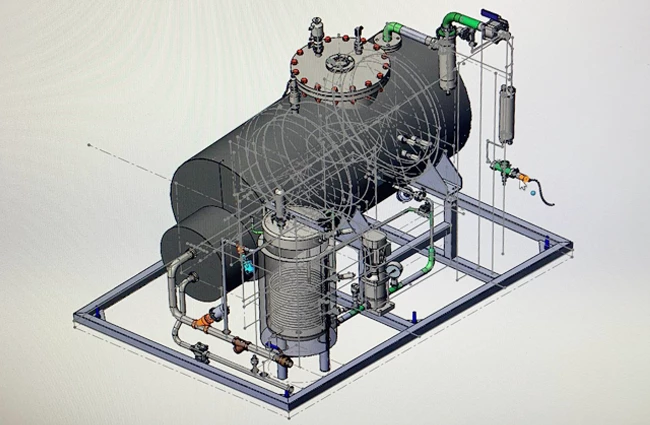

Adaptable to every stage of the process

From small R&D volumes to large GMP production capacities, our configurations fit your needs and grow with you.

Your processes don’t just need equipment; they need solutions that anticipate challenges, optimise production and ensure quality at every step.

How the Pharmabios bioreactors work

The operating principle is designed to ensure reproducible and validated results in every batch, while maintaining operational efficiency.

Culture medium loading

Addition of inoculum

Bioreaction

Unloading

CIP/SIP

Control of key parameters

01. Culture medium loading

Precise addition of the required volume to optimise the bioreaction. /p>

02. Addition of inoculum

Controlled introduction of the culture.

03. Bioreaction

Continuous monitoring of critical parameters such as temperature, pH, dissolved oxygen and optical density.

04. Unloading

Transfer of the product to subsequent stages, minimising losses.

05. CIP/SIP

Automated cleaning and sterilisation, ready to ensure consistency and avoid any risk of contamination.

06. Control of key parameters

temperature, agitation, oxygen control, pH and foam. ….

Our teams don’t just work: they anticipate and solve potential failures with state-of-the-art technology.

Guaranteed regulatory compliance

Guaranteed regulatory compliance

Full and flexible control

Full and flexible control

Tailor-made design for each client

Tailor-made design for each client

Complete technical documentation

Complete technical documentation

High quality components

High quality components

Specialised technical advice

Specialised technical advice

Customisation options

Customisation options for bioreactors and fermenters

Every operation has unique needs. That’s why we design fully customised equipment that evolves with your objectives.

Advanced parameter control

Configuration for optical density, biomass and gases (N₂, CO₂, O₂) according to process requirements.

Continuous or anaerobic operation

Specific preparation for processes with constant flow or anaerobic cultures, adapted to your objectives.

Integrated load cells

For accurate real-time monitoring of volumes and masses.

Customised heating

Options such as electric heaters to maintain optimal temperatures in any environment.

Control system expansion

SCADA and PLC systems with customised interfaces for integration with other equipment and greater operational versatility.

Chart recorder and technical documentation

6-channel recording and additional copies of protocols and manuals to comply with international audits and regulations.

When every parameter counts, every piece of equipment matters

Our bioreactors and fermenters are designed to make your production more efficient, comply with the most demanding regulations, and overcome the challenges of a constantly innovating sector.

In addition to advanced technology, you have at your disposal a team committed to you from day one. From installation to ongoing support, we make sure your processes run with the precision you need.

Grow your production with equipment that is designed to make a difference.

Frequently Asked Questions about our Bioreactors and Fermenters

Do you have more questions?

Let’s talk about your specific needs.