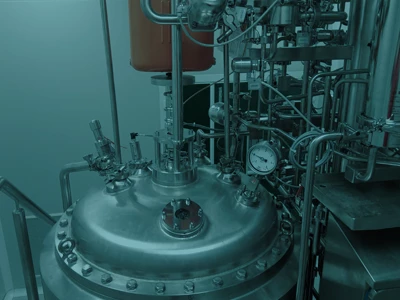

CIP+SIP cleaning systems

Our CIP systems are designed to transform cleaning processes into a competitive advantage

Compact cleaning, great results

Our equipment is designed to adapt to any plant without sacrificing a millimetre of efficiency.

In less than 60 minutes

An optimised cleaning cycle. Adjust pressure, flow and temperature with the precision you need.

Technology that facilitates processes

Regulations under control

Our CIP cleaning systems are designed to transform cleaning processes into a competitive advantage. They are efficient, sustainable, and comply with the most demanding regulations.

Cleanliness is the invisible engine of your production

When something goes wrong, the impact is immediate. With Pharmabios CIP cleaning systems, every one of these obstacles has a solution.

Downtime stopping your production lines?

We design fast, accurate cleaning cycles that minimise downtime. Your equipment will be ready before you know it, maximising utilisation and ensuring productivity.

Inconsistent cleaning results?

Forget about persistent residues or irregular cycles. With validated and parameterised cleaning, every corner of your equipment is spotless, with no exceptions or surprises.

Do you overspend resources on every cleaning?

Our commitment to the health of the planet motivates us to optimise the consumption of water, detergents and energy, ensuring impeccable results without compromising the environment. Your budget will thank you, and so will the planet.

Demanding audits?

Ensure compliance with regulations such as GMP and FDA from day one. Our systems are designed to pass inspections with confidence and ease. With Pharmabios CIP cleaning systems, you turn everyday challenges into competitive advantages: efficient cleaning, total control and regulatory compliance.

CIP+SIP cleaning systems • Maximum precision and control

Your Process, Cleaner. Your Production, More Efficient.

Cleaning is not a secondary task

it is a matter of quality, safety and time. Every minute your equipment sits idle directly impacts your bottom line.

That’s why our solutions are designed to go beyond the basics:

Pharmaceutical industry

We implement systems that guarantee the cleanliness of critical equipment without compromising your production deadlines.

Biotechnology

We seek surgical precision, advanced technology and impeccable regulatory compliance.

Medical device manufacturers

Cleanliness is not an extra step, it is a promise of quality that underpins confidence in every product.

We tailor each solution to your equipment, your timescales and your standards. Each configuration is unique, because we understand that in our industry there is no room for error.

Perfect fit, no exceptions

Each of our CIP systems is designed with your specific needs in mind. From the type of product to the characteristics of your plant.

More cleanliness, less waiting

With cycles that maximise every second, your equipment will be up and running in record time. Less downtime means more production.

Delivering has never been easier

A system that evolves with you

Pharmabios CIP cleaning systems

Each cycle combines advanced technology, automated control and regulatory compliance, ensuring reproducible results that maintain the quality and safety of the most demanding processes.

Why Pharmabios?

Compact, but unbeatable

We design modular systems that make the most of every centimetre of your plant without sacrificing performance. Ideal for installations with space limitations that do not compromise on efficiency.

Automation to the millimetre

Adjust critical parameters such as pressure, flow and temperature with a precision that eliminates any margin of error. Every cycle is reproducible and validated, because consistency is non-negotiable.

Materials that meet and exceed

We use pharmaceutical grade components and state-of-the-art technology, ensuring that everything is aligned with the most demanding international regulations: GMP, FDA, EMA.

Designed for your specific challenges

Built to last

Choosing Pharmabios is not just about choosing a supplier, it’s about adding to your team a strategic partner who understands your goals and turns them into results.

CIP cleaning stages: precision in every step

CIP cleaning stages: precision in every step

At Pharmabios, every stage of CIP cleaning is designed to ensure consistent, safe and validated results.

01. Initial rinse

The cycle starts by removing visible residues with a controlled water flow. This step prepares the equipment for chemical cleaning and ensures that no residues are left to compromise the following stages.

02. Main wash

This is where a customised solution, adjusted in concentration and temperature, comes into action, which dissolves and removes microscopic contaminants. This wash not only cleans, but also protects the most sensitive components of your equipment.

03. Final rinse

The last step removes any traces of detergent or contaminants, leaving the equipment perfectly clean and ready to operate in complete safety.

Initial rinse

Main wash

Final rinse

Uniform, risk-free cleaning designed to ensure validated cycles by controlling critical parameters such as:

Full and validated coverage

Full and validated coverage

Optimal contact times

Optimal contact times

Controlled turbulence and flow

Controlled turbulence and flow

Pressure and temperature accuracy

Pressure and temperature accuracy

Quality of the final rinse

Quality of the final rinse

Total adaptation to your processes

Total adaptation to your processes

Exclusively designed CIP cleaning systems

We adapt each CIP system to your production

Tailor-made flow rates and pressures

We configure every parameter to suit the behaviour of your products and the specifications of your plant. Because precision is key when it comes to validated cleaning.

Heating options to suit your processes

From electric heaters for flexibility to advanced heat exchangers that optimise energy consumption.

Return control that goes beyond

We incorporate return lines with conductivity measurement to maximise efficiency and ensure a fully controlled process.

Compatibility with specific detergents

We know that not all products are the same, that’s why we design systems capable of working with a wide range of detergents and chemical solutions.

Future-proofed

Our systems are designed to grow. From adding functionality to implementing advanced enhancements, we evolve with your needs.

Do your processes need a tune-up?

Talk to our CIP experts and find out how we can adapt to your needs.

Frequently Asked Questions about our CIP cleaning systems

Do you have any further questions? ?

Talk to our experts to resolve any doubts and find the solution your process needs.