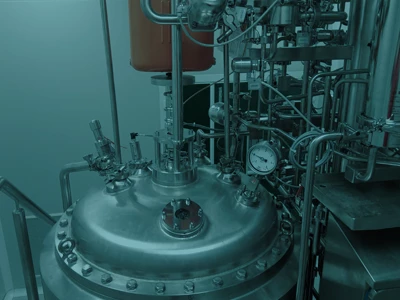

Purification systems

From chromatography to nanofiltration, each skid is a strategic solution designed to transform your processes

Compact and customisable design

Configurable recipes

Uninterrupted flows

Absence of dead sections to guarantee impeccable purification.

Beyond standards

Our purification systems are the perfect combination of technology, intelligent design, and operational flexibility. Your next leap in quality starts now.

With Pharmabios, every challenge finds a precise answer

Pharmabios purification systems not only solve problems, but open the door to more efficient, cost-effective and reliable processes.

Uncompromising quality

Our systems ensure the removal of impurities with precise separation, guaranteeing that each product meets the highest standards of purity.

Adaptable processes

With adjustable configurations, each production step is tailored to maximise efficiency without compromising quality.

Optimised space, without sacrificing performance

Compact, modular designs that make the most of every metre of your facility, making it easy to integrate even in tight spaces.

Compliance assured

Each system reflects our commitment to sustainable and responsible processes, contributing to the health of the planet while ensuring regulatory compliance.

Purification systems • Impeccable results, batch after batch

Each skid is a strategic solution designed to transform your processes.

We design more than just equipment: we design confidence

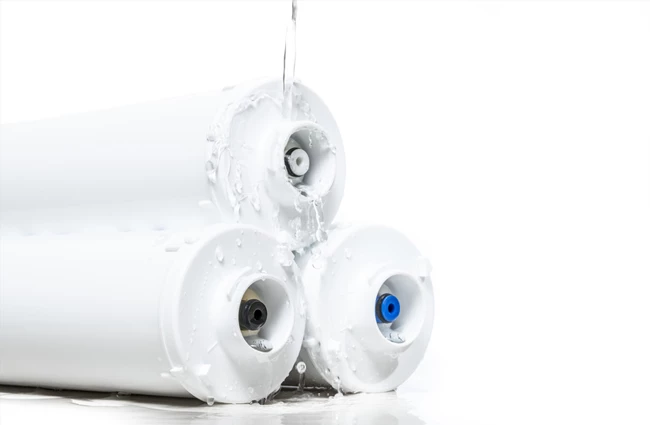

Guaranteed Purity

Each component is designed to ensure sterility and total elimination of impurities.

Operational Versatility

Compatible with chromatography, diafiltration, ultrafiltration and nanofiltration.

Pharmabios Purification Systems

Why Pharmabios

Perfect surfaces for demanding processes

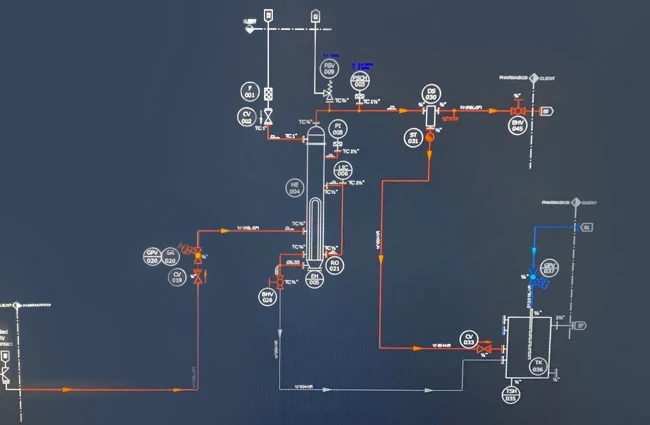

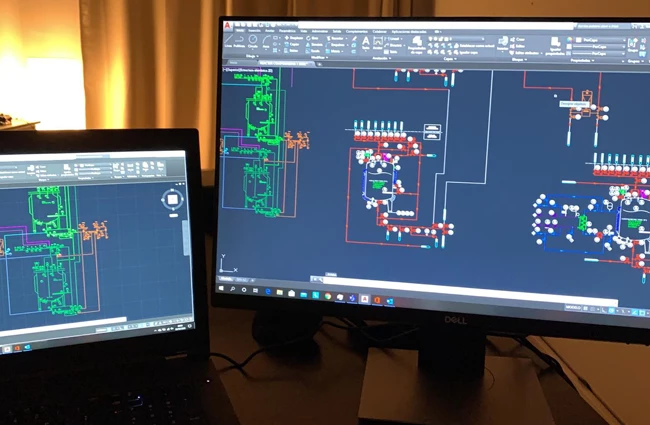

HMI and SCADA systems with Siemens PLC for intuitive and precise management of every process parameter.

Complete documentation

Adapted to the pharmaceutical industry

Operation of purification systems

Each Pharmabios purification skid is designed to ensure efficient, automated and validated operation at every stage:

Initial loading

Separation and purification

Concentration or buffer change

Viral reduction

Cleaning and disinfection

01. Initial loading

Preparation of the initial solution to optimise purification.

02. Separation and purification

Control of flow, pressure and temperature to accurately separate impurities.

03. Concentration or buffer change

Optimisation of the final product according to specific customer requirements.

04. Viral reduction

Application of advanced techniques to ensure maximum product safety.

05. Cleaning and disinfection:

Fully automated to maintain sterility in each cycle.

We adapt each piece of equipment to the needs of your process, ensuring maximum precision and efficiency.

Reproducible results

Reproducible results

Compact and mobile

Compact and mobile

International standards

International standards

Advanced customisation

Advanced customisation

Intuitive management

Intuitive management

High-end components

High-end components

purification skids

Types of purification skids

Separation of impurities by molecular exclusion, ion exchange or affinity.

Customisation options available

Advanced parameter settings

Buffer change control

We simplify your purification systems and improve your production

Our purification skids combine operational efficiency, seamless integration and a design that optimises resources without compromising quality.

Every detail is fine-tuned so that your processes not only meet standards, but make a difference in a competitive market.

Our commitment is not just to provide you with equipment. It is to accompany you with solutions that anticipate challenges, optimise your resources and contribute to a more sustainable future for industry and the planet.