Scaling Mammalian Cell Culture: Lessons from Biopharma

Mammalian cell culture has long been at the heart of biopharmaceutical manufacturing. But today, its impact goes far beyond health. From cultivated meat to cosmetic biomaterials, the challenge is no longer whether mammalian cells can be engineered — but how to produce them at industrial scale. That shift requires more than science: it demands engineering. This article explores how decades of experience in biopharma are now informing new industries, and what lessons still apply when scaling up mammalian cell culture.

What Biopharma Taught Us about Mammalian Cell Culture:

For over 30 years, the biopharma industry has optimized the large-scale culture of mammalian cells — especially CHO lines — for the production of monoclonal antibodies, vaccines and biologics. This legacy offers key insights for any company working with mammalian cells today, regardless of the final application. The most valuable lessons?

-

Precise environmental control – pH, dissolved oxygen, temperature, and CO₂ must be continuously monitored and adjusted. Even small fluctuations can compromise viability and yield.

-

Serum-free media – Biopharma pioneered the use of chemically defined, animal-free media to reduce variability, cost, and regulatory complexity.

-

Single-use bioreactors – Widely adopted to accelerate setup, avoid cross-contamination and minimize cleaning requirements.

-

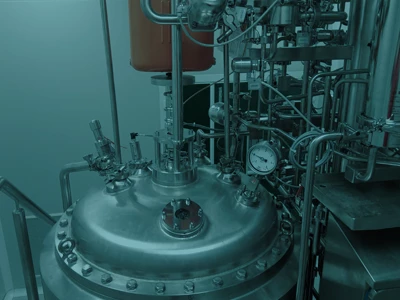

Scalability – From 2D plates to 2000-liter stirred-tank bioreactors, suspension cultures have made industrial-scale production a reality.

These practices now serve as a proven foundation — not just for pharmaceuticals, but for foodtech, cell-based cosmetics, and other biotech frontiers.

Scaling Beyond Pharma: Challenges in New Sectors

While many technologies are transferrable, scaling mammalian cell culture in sectors like food or materials science presents unique obstacles:

-

Cost pressure – Unlike biopharma, where high margins justify complex processes, food applications demand radically lower costs per gram of biomass.

-

Scale over purity – The goal is not to purify a molecule to 99.99%, but to produce tons of biomass safely and consistently.

-

Public perception and transparency – With cultivated foods or GMOs, consumers demand full traceability and ethical clarity.

-

Infrastructure – New industries often lack the cleanroom legacy and in-house expertise of pharma — making engineering support even more critical.

Success in these fields means rethinking everything — from the media to the energy footprint, from logistics to final regulatory compliance.

The Future of Mammalian Cell Culture Is Convergence

As more industries adopt and adapt mammalian cell culture technologies, we are not reinventing the wheel — we are refining and scaling it. The next phase of innovation will come from convergence: the integration of AI-driven process control, modular and continuous bioproduction systems, and recyclable, cost-efficient culture media. At the same time, the growing demand across sectors is pushing for standardization in bioreactor design and flexible manufacturing platforms.

The maturity of biopharma should not be seen as a constraint, but as a foundation. Every validated bioprocess, every optimized cell line, and every GMP-compliant batch contributes to a shared roadmap. We are not starting from scratch — we are accelerating toward a future where scalable mammalian cell production becomes a cornerstone of multiple industries.

How Can Pharmabios Support Your Scale-Up?

At Pharmabios, we specialize in helping companies transition from discovery to industrial implementation. Whether your work involves health, alternative proteins, or mammalian cell-based cosmetics, we provide tailored support to help you scale effectively. From process design and bioreactor selection to media optimization, GMP-readiness, and pilot plant development, our team combines deep bioengineering expertise with real-world experience in regulated environments.

If your current challenge is to scale mammalian cell culture with precision, compliance, and speed — we’re here to build the right solution with you.

Want the full technical article in Word format?

Just reach out through our contact form and write: «Mammalian Cell Culture Paper 1» in the message field.